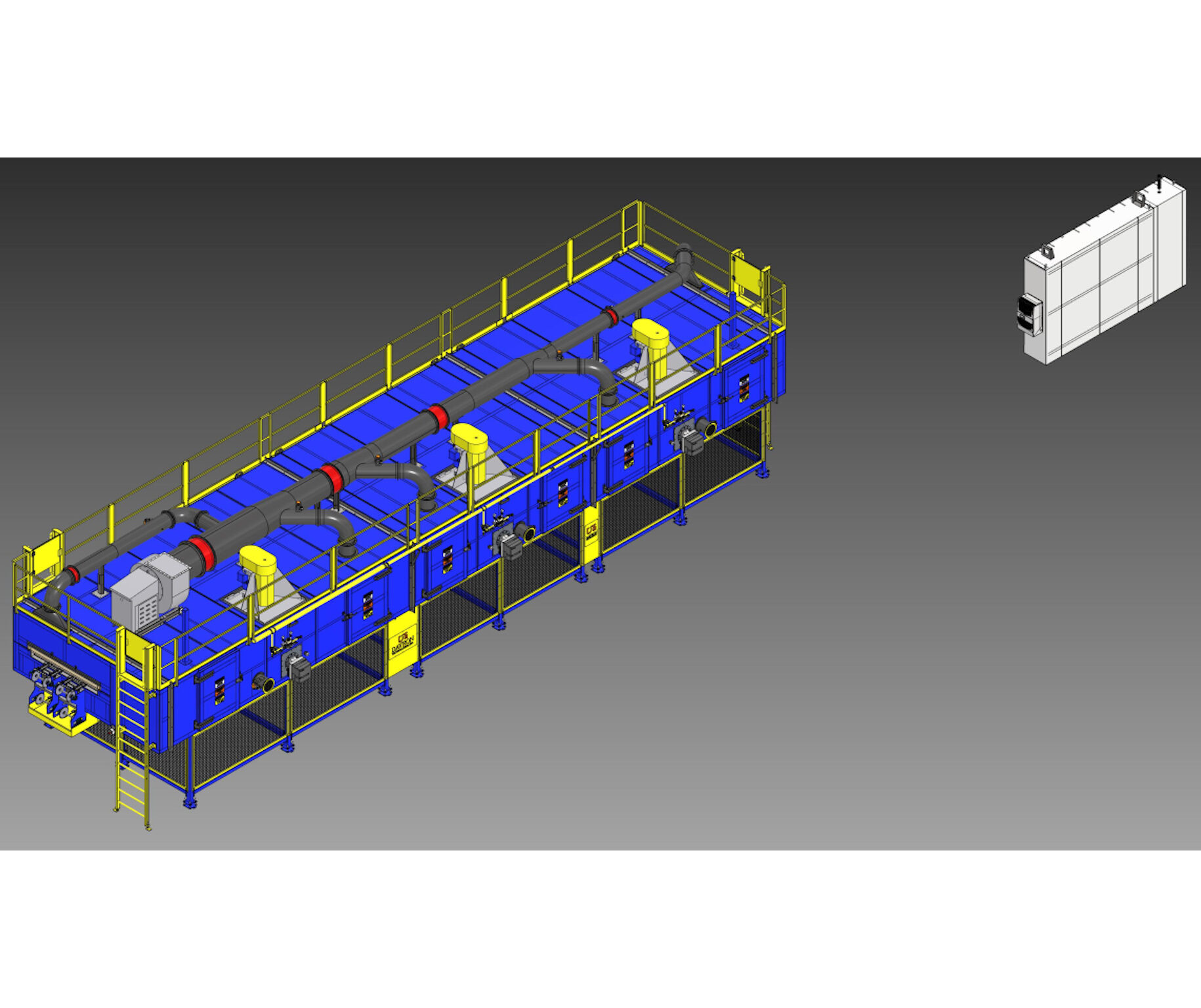

DTI-1516 Preheat Conveyor Oven

Customer directive

DTI-1516 was one of many pieces designed, manufactured, and integrated into a production line. This specific oven was designed to preheat wood siding products prior to a coating process. In order to achieve a successful coating process, the panels and boards need to exit the preheat oven at the optimal temperature. The panels and boards can potentially come from cold environments and cause issues with coating adhesion and process time. Conveyor speeds up to 325 feet per minute were required to meet their process requirements.

Description

Due to the high rate of conveyor speed (up to 325fpm) and required dwell time, there are three (3) zones of temperature control for this oven. DTI-1516 utilizes oversize roller chains with custom attachments to convey products through the heated chamber. A custom pneumatic conveyor tensioner ensures proper tension for operation even as the conveyor thermally expands and contracts and mechanically wears and stretches. A limit switch will stop the conveyor if the tensioner ever reaches the end of its travel. Plenum nozzles above the product provide top down air flow to heat the product as it is conveyed. Additionally, the system is elevated above finished floor to maintain line height through multiple process equipment.

Specifications

| Product Being Processed | Wood composite products |

| Overall System Dimensions | 62′-0″ L x 15′-5″ W x 15′-1″ H |

| Heated Chamber Dimensions | 55′-0″ L x 8′-4″ W x 1′-1″ H |

| Type of Heating System | Modulating propane fired burners |

| Design Operating Temperature | 250-400°F (121-204°C) |

| Maximum Operating Temperature | 400°F (204°C) |

| Product Support | Oversize roller conveyor chain with custom attachments |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Vertical top-down, could be from any direction depending on process requirements

- Industries Served: Building products, construction

- Materials Processed: Exterior siding, wood composites

- Other Processes: Curing, drying

- Heating Systems: Modulating natural gas or propane fired, direct or indirect heating, electric