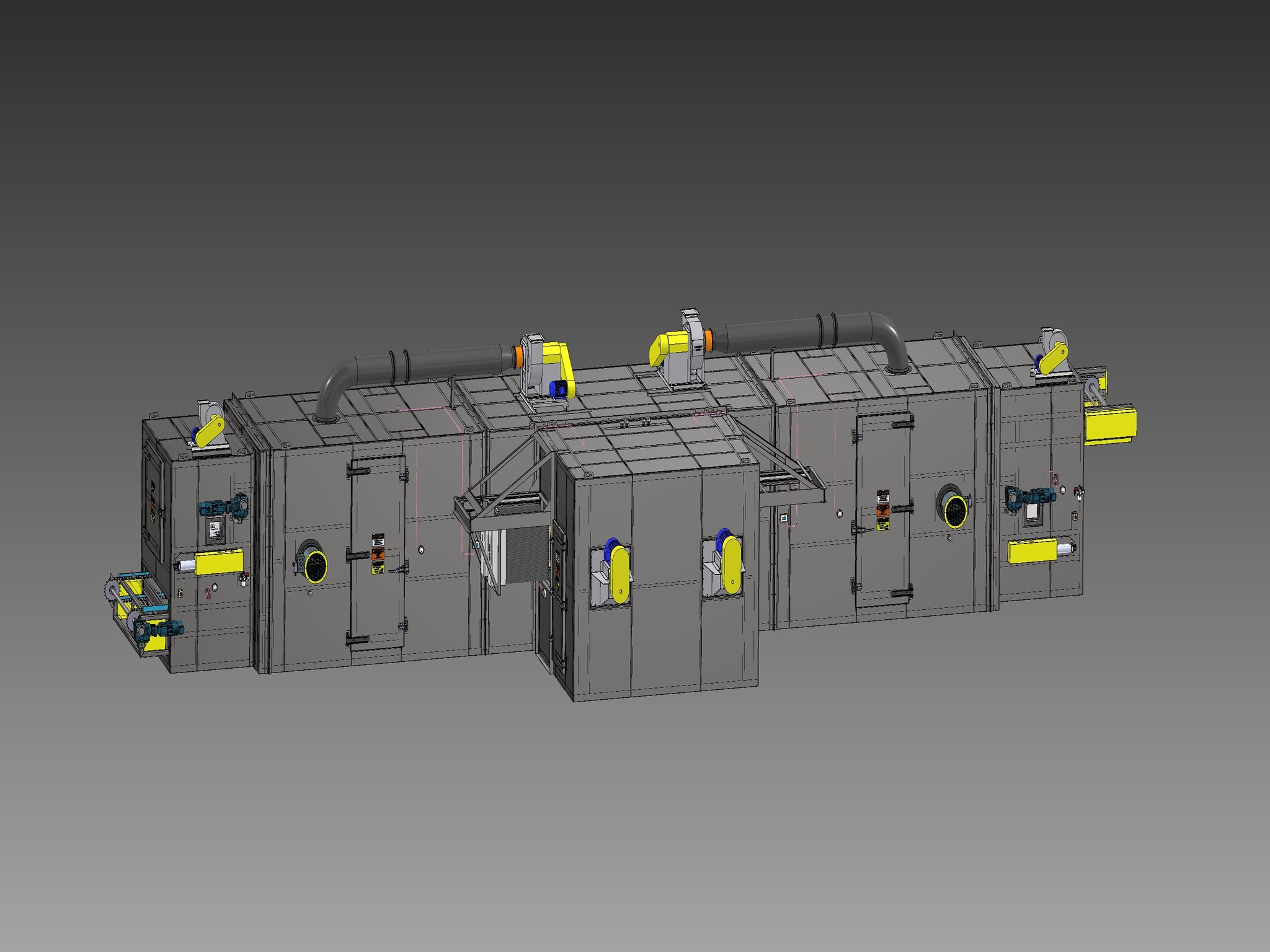

DTI-1509 Serpentine Conveyor Oven

Customer directive

The customer’s product requires a range of production rates and heating times that would have necessitated a single conveyor longer than there was space available. Horizontal airflow from the center to each end was requested to heat above and below each product pass. During the heating process, the product releases a potentially explosive amount of solvents which had to be taken into consideration.

Description

For the required production rate and heating time, a stacked triple conveyor oven was designed to reduce the overall length to approximately one third of an equivalent single conveyor. A separate air handler housing the fans and heaters was located adjacent to the oven chamber. Supply plenums were then extended into the process chamber above and below each conveyor to heat the product along it’s length. Return plenums at each end moved process air back to the air handler to be heated and recirculated. Exhaust fans, ducts, and fresh air intakes were sized to keep the amount of solvents present in the oven chamber below 25% of the lower explosive limit. An exhaust flow meter was utilized in the exhaust duct to ensure adequate exhaust at all times.

Specifications

| Product Being Processed | Insulation blankets |

| Overall System Dimensions | 100′-0″ L x 22′-6″ W x 14′-0″ H |

| Heated Chamber Dimensions | 80′-0″ L x 7′-2″ W x 8′-4″ H |

| Type of Heating System | Electric |

| Design Operating Temperature | 572°F (300°C) |

| Maximum Operating Temperature | 662°F (350°C) |

| Product Support | Oversized roller hollow pin stainless conveyor chain with machined rods |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Top and Bottom, Horizontal cross-flow, Bottom Up, Horizontal center-out

- Industries Served: Automotive, Electronics, Aerospace, Composites, General Manufacturing, Batteries

- Materials Processed: Insulation blankets or any web-type product

- Other Processes: Preheating, curing, drying, solvent removal, bonding

- Heating Systems: Electric, modulating gas fired direct or indirect