DTI-1478 Annealing Batch Ovens

Customer directive

This customer is a global provider of clean fuel solutions for commercial vehicles and gas transportation solutions. Its product offerings include natural gas storage and delivery systems, Type 4 composite natural gas cylinders, as well as propane and natural gas fuel systems. These products transport clean gaseous fuels and enable vehicles to reduce emissions while saving operating costs.

Description

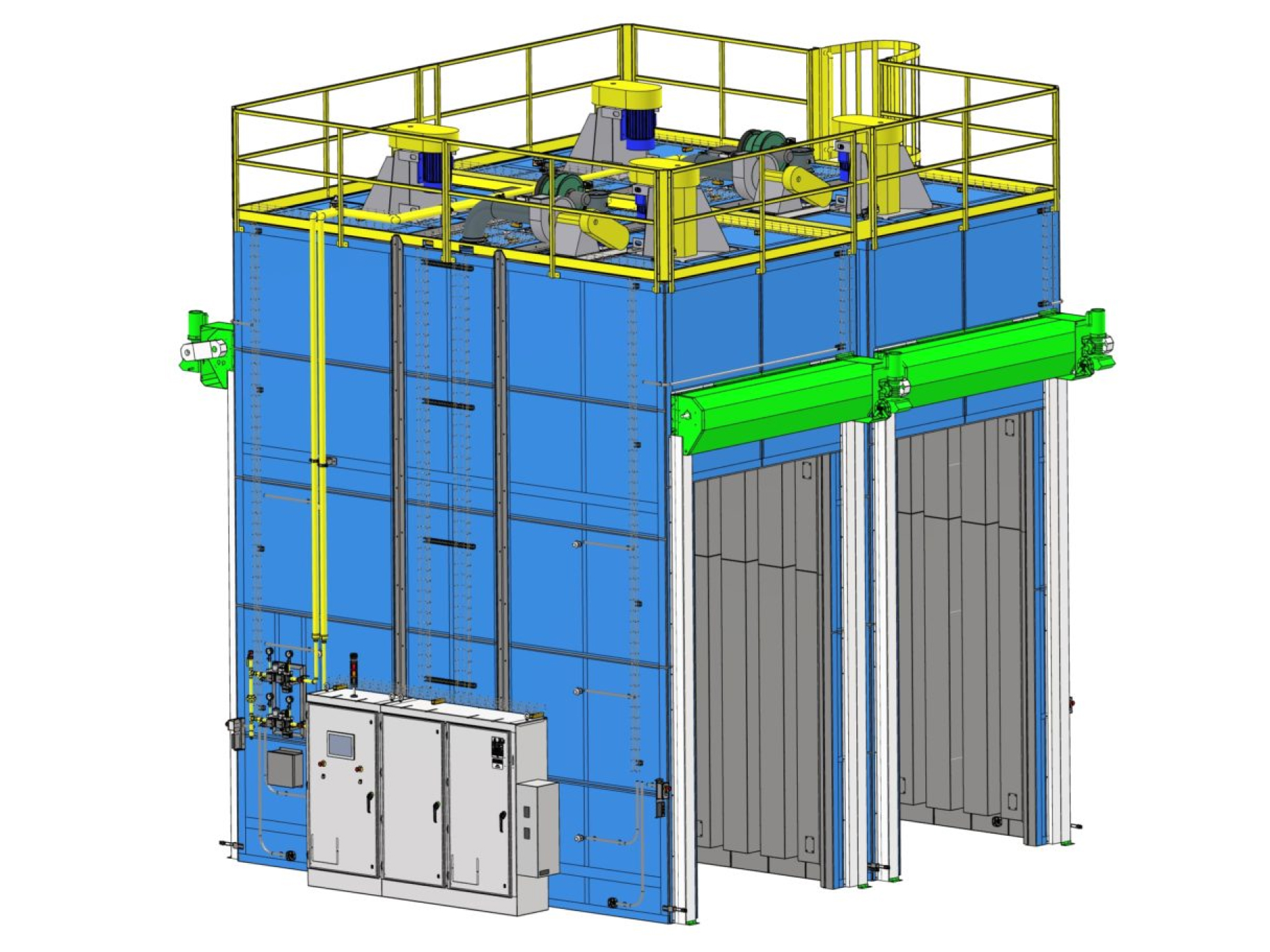

This process is required to heat extruded HDPE tubes and molded dome fuel cells in order to be welded and molded to finish the fabrication process. The system includes one circulation fan per chamber to force heated air in a vertical down direction as well as one exhaust fan to help maintain temperature uniformity throughout the oven. The oven is heated with a natural gas burner system to increase operational efficiency. The product is loaded and unloaded manually on carts with a fork truck, so the doors needed to be sized correctly in order to fit load/unload vehicles into the chamber. The load/unload doors are vertical roll-up doors to save on floor space as well as overall height of the equipment. The circulation and exhaust fans are located on the oven roof that can be accessed by a caged ladder and safety handrail along the top of the oven system for maintenance if required.

Specifications

| Product Being Processed | Extruded HDPE tubes and molded domes |

| Overall Length, Width, and Height | 18′-10″ L x 9′-0″ W x 20′-0″ H (5740mm x 2743mm x 6096mm) |

| Heated Chamber Length, Width, and Height | 17′-0″ L x 6′-0″ W x 13′-7″ L (5182mm x 1829mm x 4140mm) |

| Type of Heating System | Natural Gas Burner Package |

| Design Operating Temperature | 180-350°F (82-177°C) |

| Maximum Operating Temperature | 400°F (204°C) |

| Product Support | Manually loaded/unloaded product carts |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Designs can be completed to provide airflow from any direction within the heated chamber as required by the product. This particular process supplies horizontal crossflow from both side, from front to back, but it could be be vertical up/down, or horizontal from either side.

- Industries Served: Aerospace, composite fabrication, general manufacturing, powder coating

- Materials Processed: Carbon fiber, fiberglass, Kevlar, steel, aluminum, etc.

- Other Processes: Annealing, drying, baking, thermoforming, pre-heating, stress-relieving

- Heating Systems: Modulating Gas Fired Direct or Indirect, Electric, or Thermal Oil.