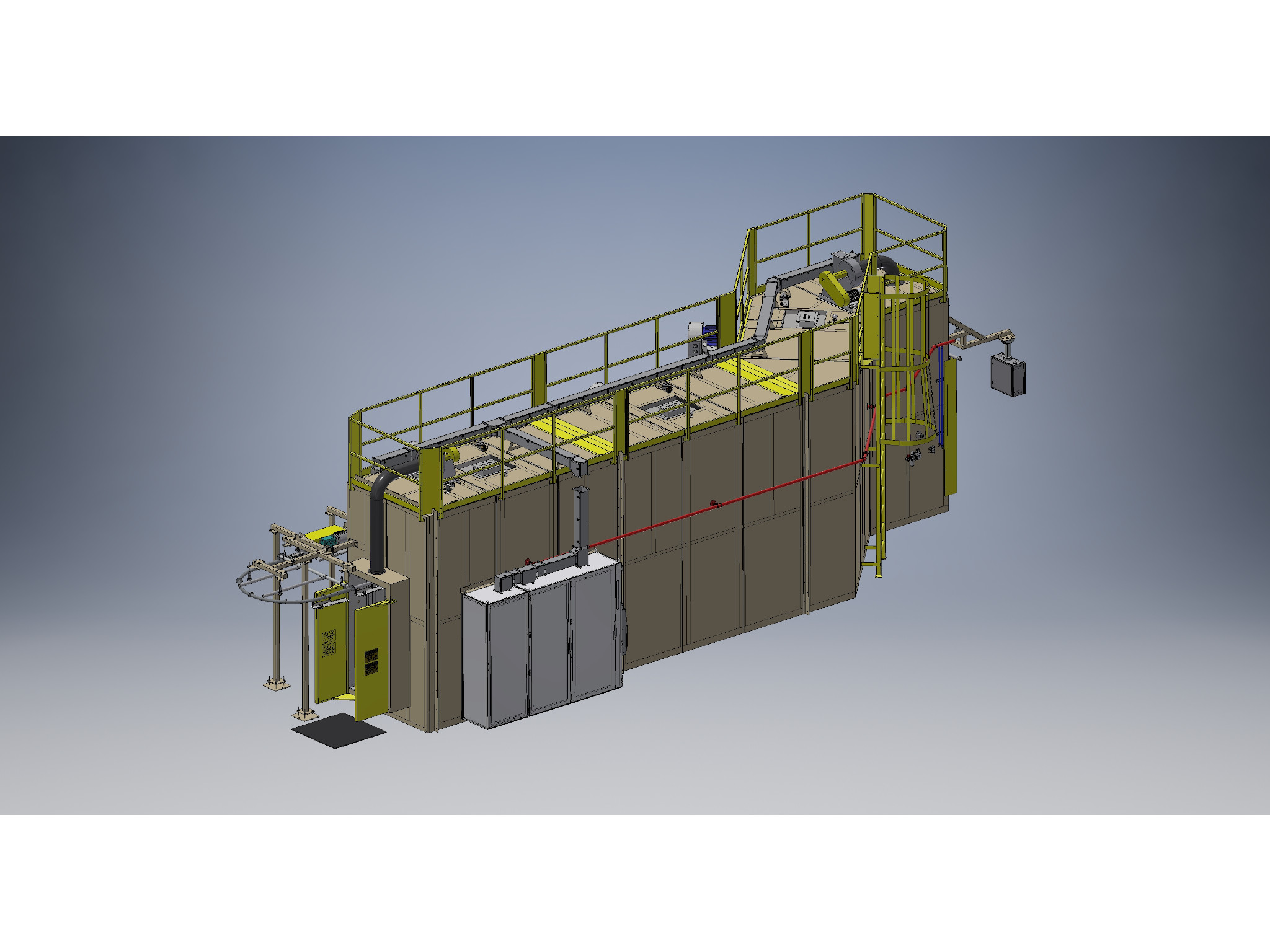

DTI-1423 Custom IP Oven

Customer directive

The customers part was an instrument panel for the automotive industry and had an irregular shape that changed periodically with new products. An overhead rail conveyor with a simple two bolt connection was provided so that different tooling could be attached to the conveyor to accommodate a wide range of parts. The path and shape of the conveyor through the oven was designed to accommodate the customers available floor space, existing equipment, and building columns.

Description

DTI-1423 is an indexing conveyor oven. Parts are loaded and unloaded on the conveyor manually and the number of parts conveyed into and out of the oven during each index is set on the HMI depending on the customers process requirements. Likewise, the index time is also set on the HMI for the desired amount of heating time. Heating is accomplished with electrically heated forced air convection. The part is irregular and impermeable, so heated air comes from the bottom and both sides for uniform heating of the part. Laser sensors count the number of indexed parts and stop the conveyor in the same spot consistently. The exit end of the oven features a pneumatically actuated automatic insulated door that closes around the conveyor rail and in between the hanging parts to retain as much heat as possible in between indexes. Due to thermal expansion and wear of the conveyor chain, an exhaust vestibule is utilized on the entrance end in lieu of a door to keep heat from escaping into the plant.

Specifications

| Product Being Processed | Instrument Panels / Dash Boards in the Automotive Industry |

| Overall Dimensions | 50′-0″ L x 16′-2″ W x 14′-10″ H (15240mm x 4928mm x 4521mm) |

| Heated Chamber Dimensions | 36′-10″ L 3′-0″ W x 6′-5″ H (11227mm x 9144mm x 1956mm) |

| Type of Heating System | Electric duct heater |

| Design Operating Temperature | 122°F – 302°F (50°C – 150°C) |

| Max Operating Temperature | 392°F (200°C) |

| Product Support | Hanging overhead rail conveyor |

| Controls | PLC control with operator HMI, UL listed control enclosure |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Bottom up, crossflow horizontal

- Industries Served: Automotive, aerospace, general manufacturing

- Materials Processed: Plastics, metals, composites, irregular shapes

- Other Processes: Preheating, curing, drying, bonding

- Heating Systems: Electric, modulating gas fired direct or indirect