Case study: Solving automotive carpet delamination with a fully integrated production line

An automotive acoustics manufacturer needed to install a new production line. Their existing process struggled with too-frequent part imperfections due to the performance of their oven, so they came to Davron to work on an oven that could solve their problem.

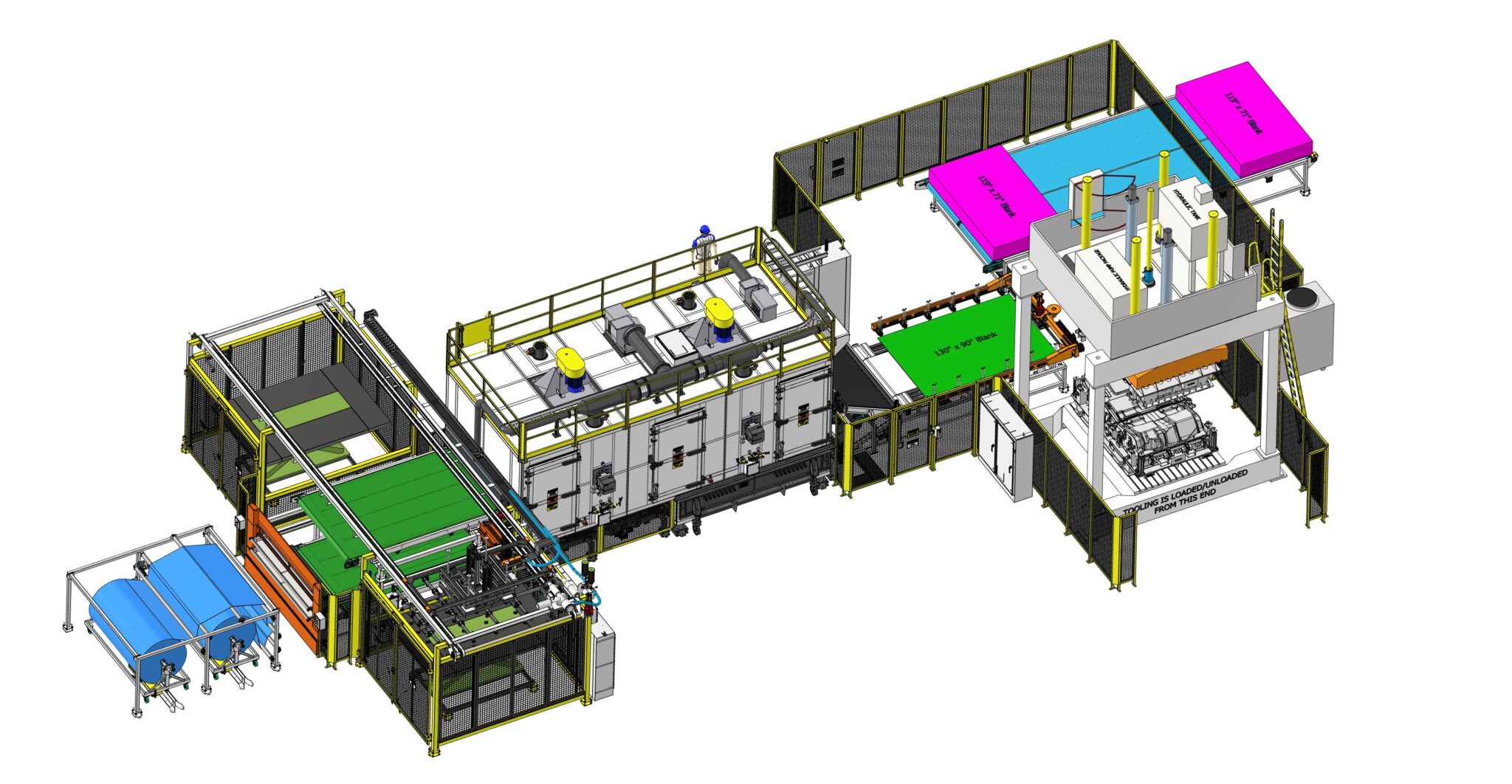

Months later, we shipped and installed a fully integrated production line that produces a perfect part every two minutes using a thermal process the manufacturer had never attempted before.

Here’s how we made it happen.

How their product was failing

Automotive acoustic carpet is formed from multiple separate layers. This customer loaded all three layers of their carpet into a heated press, which would heat and set the adhesive when it pressed the parts together.

This acoustic carpet manufacturer was experiencing a common challenge — delamination after coming out of the press. Too often, the center of their part wasn’t getting enough heat, and when the press would separate, it would pull the layers back apart.

This created too much scrap, necessitated a lot of rework and led to inconsistent production volumes.

Proposing an entirely different thermal process

We’d seen this exact challenge before and knew the best way to solve it was to ditch the contact heat and move to another heating method altogether: Convection heat at different temperatures for each layer, to pre-heat them to different levels.

The only thing in the way of moving forward: Our customer had never used convection for this product before.

“They had a lot of skepticism,” says Stephen Snyder, equipment designer at Davron. “They were very comfortable with contact heat, and they had a long history of it, so they knew they had some ability of succeeding. This was kind of a big risk to trust that this new way of doing it — new to them — would work.”

We would need to prove that our method could work with some pre-engineering and front-end testing.

Learn more about implementing a new automotive textile thermal process. From design and personnel decisions to startup and training.

Download our guideProving out our proposed solution

We scheduled a demonstration with the customer and worked on developing an example of the oven we’d build them, for proof-of-concept. We just needed to apply what we learned from numerous similar ovens we’d built in the past to the exact specification the customer required.

“We brought them in house and explained the way that we have done it in the past, and we actually had a machine that was very similar to what they were looking at,” Stephen says. “They brought their material up here, we cut up samples of it and we did exactly what we told them we would do.

With the customer on-site and a test oven ready to go, we put together a small press set up and performed test samples to show them our solution in action. After a few runs, their skepticism faded — and engineering conversations gained positive momentum.

“They all sat there and tried to rip it back apart and looked at each other like, ‘Oh this works really well.’”

The customer went back and did some thinking of their own before agreeing wholeheartedly on our concept. Then we started engineering the details and building the oven — but not only the oven.

Integrating a complete production line

When manufacturers are looking for a new thermal process, they usually aren’t only in need of an oven. Modern production lines are highly integrated systems with multiple pieces of equipment working as one, simultaneously.

Sourcing and supporting equipment from all over the globe to run a single production line invites a host of its own challenges, so this customer asked us to provide their entire production line. If they showed up to our equipment with rolls of carpet and cut blanks, it should produce finished product, ready for delivery.

From picking to pressing, we built a complete system in house. Every wire in the electrical panel. Every cut piece of metal. Every motion of every piece of equipment programmed into the PLC. It’s how we like to work, so we appreciated the challenge.

Integration and testing ahead of delivery

For turnkey implementations, full line installations or any projects that require multiple pieces of new equipment, installation and implementation tend to cause a lot of pain. After weeks of assembling the equipment on your shop floor, your implementation team starts the tedious work of integration.

Getting from delivery to startup can take months for complete production lines, in some cases.

Davron handles assembly, integration and testing in our own facility, so that you receive a production line that is up and running in weeks, not months.

The first time that the customer will see our fully assembled and finished production line is in our own facility, for factory acceptance testing (FAT).

“Our intent is that FAT with the customer is a demonstration of operation. We already know what it’s going to do,” says David Craft, president at Davron. “We know the handshake between machinery that’s included in that line all works. We’ve tested it, and we’ve got some runtime on it already.”

And because we build our ovens in large modules with structural steel frames, we can ship our equipment fully assembled, in modules that just need to be reattached and powered up. This way, the automotive carpet manufacturer can put in a new line without it spending months getting assembled on their shop floor.

The final product

With their new production line, the automotive carpet manufacturer will be able to produce identical parts continuously, 24/7. It’s built to outlast the product itself, and so long as they continuously feed it raw materials, they’ll produce a finished part every two minutes.

Struggling with a thermal processing problem?

Ask us about it. There’s a good chance we’ve seen it and solved it before.

If you know what you need, we can design and build an oven — or an entire production line — to meet a challenging set of specifications. If not, we can work with you to pre-engineer a quote-ready oven design that will solve your problem.